What is Dagorhir?

Forming a Unit

Aratari Units in the DC Area

Where Are Other Units?

Dagorhir Rules

Dagorhir Aratari Handbook

Battle Pictures

"How To" Pages

Announcements

Battles & Upcoming Events

Practices & Directions

Event Directions

Aratari Information Line:

301-231-3594

Join Aratari's Mailing List!

Dagorhir's National Website

Join our National Community

on the Dagorhir Bulletin

Board

Building a Dagorhir Axe

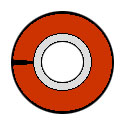

This should work for both PVC and fiberglass cores. The illustrations show PVC core.

Special thanks to Scion d'Ur of the Dagorhir Realm Angaron in Pittsburg for this incredible contribution in developing these pages, instructions, and splendid graphics. While this design is not the only one allowed or in use, it is a recognized standard highly recommended for safety and longevity.

Core:

- Start with a PVC core at least 18 inches in length.

- Secure tip of core so it doesn't poke through the padding.

Padding:

*Note about contact cement: Apply to surfaces to join lightly and allow cement to dry to a "tacky" texture before joining surfaces.

- Cover the length of the core with pipe insulation except for the grip.

- File or sand flat where the front and back of the axe head will be.

- Glue two strips of closed cell foam, about 2 inches wide, to each flat section of the pipe insulation

and bridge on tip of core with two more 2-inch wide strips of closed cell foam to create a flat top.

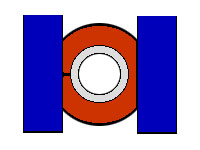

- Glue three or four 2-inch wide strips to the striking blade of the axe and one single piece of foam to cover from

the front to the back. Shape as your creativity sees fit. You might want to glue a layer of open cell foam to the

striking surface if needed. I've found that my axe blades seem a little hard for some reason. Probably because of

the concentrated weight at the tip due to the padding.

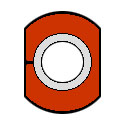

Grip:

- Attach an appropriate amount of counterweight to the bottom of the core as you find comfortable. For

an axe, you still probably want it to be head heavy to simulate the weight distribution.

- Secure counterweight and bottom of pipe insulation tightly with duct

tape.

- Cover counterweight with a thick 2-inch wide block of open cell foam and a 2-inch wide strip of closed cell

foam and secure tightly with duct tape as well as the bottom of the blade padding as shown. Remember, the pommel

cannot pass through a 2 1/2 inch diameter hole to be considered safe.

- Glue two 1-inch wide strips to the front and back of the grip. Wrap tightly to provide a wider yet firm grip.

Cover:

I can't think of any easy outs for this one. You have to pin, cut out and sew axe covers. It is tricky and expect some of your stitching to show. Remember to secure the cover to the shaft of the axe with duct tape. Cover the shaft with a brown cloth sewn up like a tube, turned inside out and pulled on from the bottom of the axe, up into place.

Now, go chop down the greatest tree in the forest with it, or would you rather use a herring?

Any comments or questions? Please email me. I would appreciate any input. - Scion d'Ur